About Solid Carbide Micro End Mill

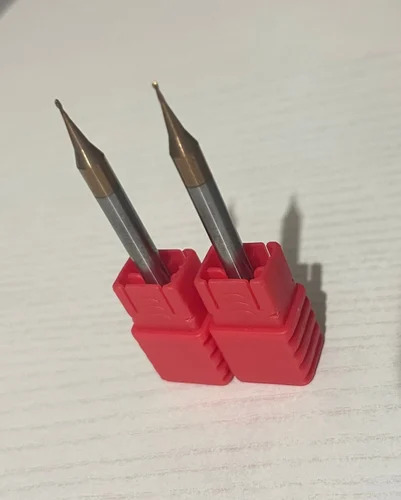

Discover the stellar Solid Carbide Micro End Mill, a hot-selling and trending solution for precision finishing tasks. Engineered with outstanding durability, this brilliant tool features a reduced diameter ranging from 0.1 to 1 mm, making it ideal for intricate operations. Crafted from high-grade carbide and coated for enhanced performance, it boasts a hardness of 50 HRC and a sleek silver finish. Available in a 4 mm size, this micro end mill is trusted by suppliers and traders across India for its exceptional reliability and operational excellence.

Exceptional Application Surface and Material Features

The Solid Carbide Micro End Mill excels in finishing operations on hard materials, delivering an ultra-smooth surface with each application. Its carbide composition ensures superior wear resistance, while a premium coating bolsters longevity and cutting efficiency. The tool's durability and reduced size make it ideal for precise machining, guaranteeing consistent results in sectors demanding fine tolerance and high-quality finishes.

FOB Port, Supply, and Sale Terms

Solid Carbide Micro End Mills are shipped from major FOB ports across India. With robust supply ability to meet demands swiftly, shipment and freight processes are streamlined for reliability and speed. The sample policy offers prospective clients access to trial pieces before bulk purchase, ensuring satisfaction at a competitive sale price. Efficient packaging and shipment guarantee optimum product condition and timely delivery, supporting large-scale industrial requirements.

FAQ's of Solid Carbide Micro End Mill:

Q: How do I select the right diameter size for my finishing operation?

A: To select the appropriate diameter size for your finishing task, consider the required precision and material thickness. The Solid Carbide Micro End Mill is available in diameters from 0.1 to 1 mm, making it suitable for micro-machining and intricate finishing work. Evaluate your project's tolerance requirements before choosing.

Q: What is the process for acquiring samples before bulk purchase?

A: You may request a sample of the Solid Carbide Micro End Mill as part of the supplier's sample policy. Contact the trader or supplier, specify your required size, and the process will include shipment and freight arrangements for delivery. This ensures you evaluate the tool's performance before finalizing a bulk order.

Q: When can I expect my shipment after placing an order?

A: After placing an order, the micro end mill will be shipped promptly from Indian FOB ports. Shipment timelines depend on order volume, location, and freight conditions. Typically, reliable and speedy shipment processes ensure you receive your products within the estimated delivery window provided by the supplier or trader.

Q: Where is the Solid Carbide Micro End Mill mainly supplied from?

A: The product is mainly supplied from various trading hubs and FOB ports across India, leveraging a wide distribution network to fulfill domestic and international orders efficiently.

Q: What are the main advantages of choosing coated solid carbide material?

A: Choosing coated solid carbide provides outstanding durability, enhanced hardness (up to 50 HRC), and superior wear resistance. This results in longer tool life, brilliant finishing quality, and reduced tool replacement costs for demanding operations.

Q: How is the Solid Carbide Micro End Mill beneficial for precision industries?

A: Its micro diameter and stellar construction allow precise machining on restricted surfaces. The reduced size, excellent hardness, and coating deliver outstanding accuracy, making it highly beneficial for industries that require high precision and reliability.