About Carbide End Mill Cutter

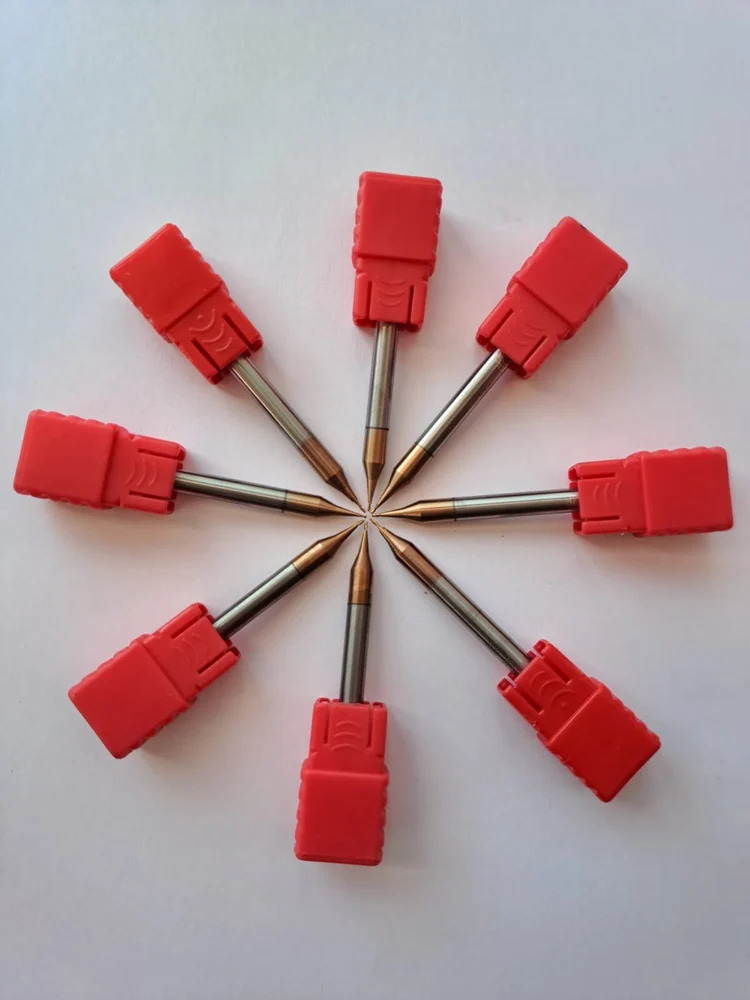

Procure first-class Carbide End Mill Cutters, a pivotal tool in finishing operations across various industries. Crafted from premium carbide material and coated for enhanced durability, these cutters are highly in demand amongst professionals seeking consistent value and performance. With a standard size and a length of 25 mm, our Ace product ensures effortless operation. The silver finish not only accentuates its quality but also signifies reliability. Sourced from a reputable supplier and trader in India, this product guarantees efficiency and longevity in every use.

Delivers Excellence for Precision Finishing

Carbide End Mill Cutters are extensively used by machinists, fabricators, and manufacturing units looking to ace precise finishing tasks. Boasting competitive advantages such as superior edge retention and minimal wear, these cutters are engineered from high-grade carbide-rendering them robust and long-lasting. Their easy-to-use design and coated finish further affirm their material features, making them a first-choice tool for exacting applications requiring dependability and precision.

Seamless Export With Ready Stock & Valuation Advantage

Our Carbide End Mill Cutters are available with speedy FOB port dispatching, ensuring quick lead times for your urgent requirements. Stock is ready for immediate shipment, with accurate valuation conducted for every order. We provide samples when necessary, making trade decisions easier. Catered to major export markets, including Asia and beyond, these cutters meet diverse global standards, guaranteeing satisfaction for all our valued international clients.

FAQ's of Carbide End Mill Cutter:

Q: How is the Carbide End Mill Cutter primarily used?

A: The Carbide End Mill Cutter is primarily utilized for finishing operations in various machining tasks, offering precision and a smooth finish on surfaces due to its robust carbide material and coated design.

Q: What makes the coated carbide material advantageous?

A: The coated carbide material enhances durability and wear resistance, enabling longer tool life and maintaining sharpness, which contributes to consistent, high-quality machining results.

Q: When can I expect dispatch after placing an order for these cutters?

A: With stock ready and streamlined processing, orders are typically dispatched promptly after payment, particularly for shipments through our designated FOB ports.

Q: Where are the main export markets for this product?

A: The main export markets for the Carbide End Mill Cutter include several Asian countries and other international territories where top-class machining tools are highly sought after.

Q: What is the sample availability process for this end mill cutter?

A: Samples can be provided upon request, allowing potential buyers to evaluate the cutter's quality and suitability before finalizing bulk procurement.

Q: How does the easy-to-use feature benefit the end user?

A: The intuitive design and ergonomic handling of the cutter make operations efficient and reduce fatigue, enabling both seasoned professionals and new users to achieve ace results effortlessly.